Key Factors to Consider When Selecting a Busbar Support for Low Voltage Switchgear

Қожалдама | Жаңалықтар | Янв 09,2026

Кіріспе

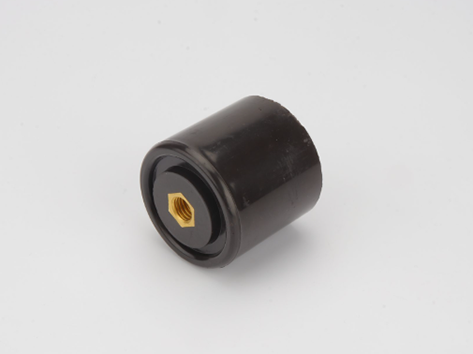

-Да low voltage switchgear systems, busbars play a critical role in power distribution, carrying high currents within compact enclosures. To ensure safety, reliability, and long-term performance, selecting the right BusBar қолдауы is just as important as choosing the busbar itself.

Электр оқшаулау көрсеткіштері

Electrical insulation is the primary function of a busbar support. When selecting a product, consider:

Dielectric strength and insulation resistance

Compliance with applicable low voltage standards

Ability to maintain required clearance and creepage distances

High-quality insulating materials help prevent short circuits, leakage currents, and flashover inside switchgear cabinets.

Mechanical Strength and Load Capacity

Busbar supports must withstand various mechanical stresses, including:

The weight of copper or aluminum busbars

Thermal expansion during current load changes

Electrodynamic forces caused by short-circuit currents

Materials such as DMC or glass-fiber-reinforced composites provide high mechanical strength and dimensional stability, ensuring reliable support over long-term operation.

Thermal Resistance and Operating Temperature

Low voltage switchgear often operates under elevated temperatures due to high current flow. A suitable busbar support should:

Maintain mechanical and electrical properties at high temperatures

Resist deformation under continuous thermal stress

Support temperature rise requirements specified in standards

Selecting materials with good heat resistance helps extend equipment service life and improves operational safety.

Flame Retardancy and Fire Safety

Fire safety is a critical consideration in enclosed electrical systems. Busbar supports should:

Meet flame retardant standards such as UL94 V-0

Limit flame propagation and smoke generation

Reduce fire risk in case of electrical faults

Flame-retardant busbar supports significantly improve the overall safety level of low voltage switchgear.

Material Selection and Environmental Resistance

Different installation environments require different material properties. When selecting a busbar support, consider resistance to:

Moisture and humidity

Chemicals and industrial pollutants

Corrosion and aging

Composite materials like DMC offer excellent resistance to harsh environments, making them suitable for both indoor and semi-outdoor applications.

Dimensional Accuracy and Design Compatibility

Қазіргі уақыттағы low voltage switchgear is becoming more compact and modular. Busbar supports should offer:

High dimensional accuracy for precise assembly

Compatibility with standard busbar sizes and mounting systems

Flexibility for custom designs

Precision-molded busbar supports help improve assembly efficiency and ensure consistent product quality.

Compliance with Standards and Certifications

Ensure that the selected busbar support complies with relevant international and industry standards, such as:

IEC standards for low voltage switchgear

UL requirements for insulation and flame retardancy

RoHS and REACH environmental regulations

Certified products reduce compliance risks and simplify project approval.

Service Life and Maintenance Requirements

A reliable busbar support should provide:

Long-term insulation stability

Resistance to thermal cycling and vibration

Minimal maintenance over its service life

Choosing durable materials reduces downtime and lowers overall operating costs.

Қорытынды

Selecting the right busbar support for low voltage switchgear involves more than just matching dimensions. Electrical insulation, mechanical strength, thermal resistance, flame retardancy, and environmental durability all play critical roles in ensuring safe and reliable operation.

By carefully evaluating these key factors, engineers and manufacturers can improve system performance, enhance safety, and meet the evolving demands of modern low voltage power distribution systems.

Жиі қойылатын сұрақтар

What is the main purpose of a busbar support in low voltage switchgear?

A busbar support secures and electrically insulates busbars within low voltage switchgear. It prevents short circuits, maintains proper clearance, and ensures the mechanical stability of the busbars under load and thermal expansion.

What materials are commonly used for low voltage busbar supports?

Low voltage busbar supports are typically made from DMC (Dough Molding Compound), BMC, or glass-fiber-reinforced thermosetting composites. These materials provide excellent electrical insulation, mechanical strength, flame retardancy, and resistance to heat and environmental stress.

How do I choose the right busbar support for my switchgear?

Key factors include:

Electrical insulation properties (dielectric strength, creepage, clearance)

Mechanical strength and load capacity

Thermal resistance and operating temperature

Flame retardancy and fire safety compliance

Environmental resistance (humidity, chemicals, corrosion)

Dimensional accuracy and design compatibility

Compliance with standards (IEC, UL, RoHS, REACH)

Are busbar supports flame retardant?

Yes. High-quality low voltage busbar supports meet flame retardant standards such as UL94 V-0, helping to reduce fire risks in enclosed electrical systems.

Can busbar supports be used in outdoor environments?

Composite busbar supports with corrosion and moisture resistance can be used in outdoor or semi-outdoor environments, such as solar power systems or industrial distribution cabinets, provided they are installed in suitable protective enclosures.

How long is the service life of a busbar support?

High-quality busbar supports can last 10–20 years or more, depending on operating conditions, material selection, and exposure to environmental stressors.

--- СОҢЫ ---

© Copyright 2024 China Haitan электромеханикалық технологиясы Co., Ltd. Барлық құқықтар қорғалған.Қолдау: junj Құпиялылық саясаты

E-mail:

E-mail:  №20 Лингюн жол, донгфенг

№20 Лингюн жол, донгфенг