The Practicality of Color Coding and the Application Value of Multi-Color DMC Insulators in Distribution Cabinets

บล็อก | ห้องข่าว | ก.พ. 02,2026

การแนะนำ

As distribution cabinets and switchgear systems continue to evolve toward higher density, modularization, and intelligent management, clarity, safety, and efficiency have become critical design considerations. Beyond mechanical strength and insulation performance, component identification and visual management now play an increasingly important role.

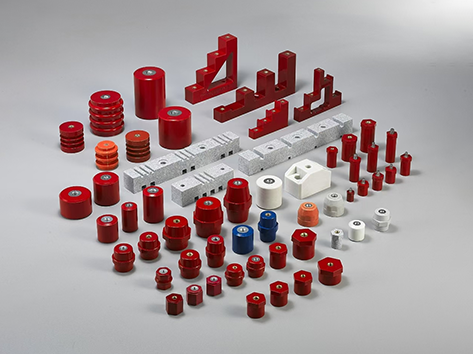

DMC (Dough Molding Compound) insulators, known for their high mechanical strength and excellent electrical insulation properties, offer an additional advantage: flexible color customization. The use of multiple colors in DMC insulators brings significant practical value in circuit identification, voltage classification, phase distinction, and maintenance safety.

Why Color Coding Matters in Distribution Cabinets

In modern distribution cabinets, internal layouts are becoming more compact, with dense busbar arrangements and complex circuit structures. Traditional identification methods—such as labels, markings, or drawings—can be insufficient in real-world installation and maintenance scenarios.

Color coding provides instant visual recognition, allowing engineers and technicians to quickly identify system functions without relying solely on documentation. This visual differentiation is especially valuable in:

Multi-circuit systems

Mixed voltage levels

Three-phase power distribution

Modular or expandable cabinet designs

By integrating color coding directly into insulation components, identification becomes permanent, intuitive, and resistant to wear or mislabeling.

Multi-Color DMC Insulators: Material and Manufacturing Advantages

DMC is a thermosetting composite material composed of polyester resin, glass fiber, fillers, and additives. Its molding process allows pigments to be uniformly integrated into the material during production.

Compared with surface painting or post-processing coloring, color-customized ฉนวน DMC offer:

Consistent color throughout the structure

No peeling, fading, or contamination

Long-term color stability under heat and UV exposure

No impact on mechanical or electrical performance

This makes DMC insulators particularly suitable for long-life electrical equipment operating in demanding environments.

Application Scenarios of Color-Coded DMC Insulators

Circuit Identification

Different colors can be assigned to different outgoing or incoming circuits within the same cabinet. This allows installers to quickly match physical components with schematic designs, reducing wiring errors during assembly and commissioning.

Voltage Level Differentiation

In cabinets containing multiple voltage levels (such as control circuits and power circuits), color-coded insulators help clearly separate high-voltage and low-voltage areas. This visual separation enhances operational safety and reduces the risk of accidental contact during maintenance.

Phase Sequence Distinction

For three-phase systems, ฉนวน DMC can be customized in standard phase colors (e.g., L1/L2/L3). This improves phase consistency during busbar installation and helps prevent phase misconnection, which can cause equipment malfunction or serious system faults.

Improved Maintenance and Troubleshooting Efficiency

During inspection, troubleshooting, or component replacement, technicians can immediately locate the relevant circuit or phase based on color. This significantly shortens maintenance time and minimizes the likelihood of human error, especially in emergency repairs.

Enhancing Safety and Reducing Human Error

Many electrical accidents and system failures are caused not by material defects, but by misidentification, incorrect connections, or maintenance mistakes. By introducing color differentiation at the insulation component level, distribution cabinets gain an additional layer of passive safety.

Color-coded DMC insulators support:

Faster visual confirmation

Reduced dependence on labels and manuals

Lower training costs for operators

Improved compliance with safety management practices

บทสรุป

Multi-color ฉนวน DMC are more than an aesthetic option—they are a functional design solution for modern distribution cabinets. By enabling clear circuit identification, voltage separation, and phase distinction, color-coded DMC insulators improve installation efficiency, enhance operational safety, and reduce the risk of human error throughout the equipment lifecycle.

As distribution systems move toward higher integration and smarter operation, the application value of customizable, color-coded DMC insulation components will continue to grow, making them an important choice for manufacturers and system designers focused on reliability and safety.

คำถามที่พบบ่อย

Q1: Does color customization affect the electrical or mechanical performance of DMC insulators?

No. Color pigments are integrated into the DMC material during the molding process and do not alter its dielectric strength, mechanical load capacity, or thermal stability. Properly formulated DMC insulators maintain the same insulation and structural performance regardless of color.

Q2: What colors are commonly used for DMC insulators in distribution cabinets?

Common colors include red, yellow, blue, black, white, and green. These colors are often selected based on circuit identification, voltage levels, or phase sequence requirements. Custom colors can also be produced to match specific project standards or customer specifications.

Q3: Can multi-color DMC insulators be used to identify different voltage levels?

Yes. Color coding is an effective method to visually distinguish between high-voltage and low-voltage circuits within the same cabinet. This helps improve operational safety and reduces the risk of accidental contact during installation and maintenance.

Q4: Are color-coded DMC insulators suitable for long-term use?

Yes. Since the color is part of the molded material rather than a surface coating, it will not peel, fade, or wear off under normal operating conditions. This ensures long-term visibility and reliability throughout the service life of the equipment.

Q5: Do color-coded insulators help reduce installation and maintenance errors?

Yes. Clear visual differentiation allows technicians to quickly identify circuits, phases, and functional areas, reducing reliance on labels or drawings. This significantly lowers the probability of wiring mistakes and maintenance-related human errors.

--- จบ ---

© ลิขสิทธิ์ 2024 China Haitan Electromechanical Technology Co., Ltd. สงวนลิขสิทธิ์สนับสนุนโดย:มิถุนายน นโยบายความเป็นส่วนตัว

อีเมล์:

อีเมล์:  เลขที่ 20 ถนนหลิงหยุน ตงเฟิง

เลขที่ 20 ถนนหลิงหยุน ตงเฟิง