Tili

- Busbarni qo'llab-quvvatlash

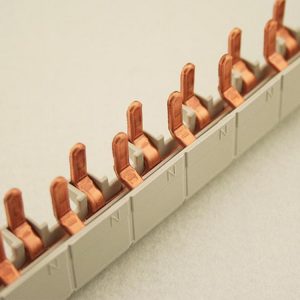

Avtobuslar panori uchun tanlov uchun avval sizning mis baringiz spetsifikatsiyasini tasdiqlang. Tasdiqlanganidan so'ng, sizning avtobuslar panelingiz qancha bosqichda, qancha pog'onalar panjarasi va har bir faza bar va boshqa bir faza bar orasidagi masofa va boshqa faza masofasi qanday fazali faza masofasi borligini tasdiqlang. Sizga kerak bo'lgan o'lcham bo'yicha turni tanlang. Umumiy naslchilik 55, 80, 100, 110, 130, 130, 160, 170, 175 va 180 (birlik: mm). Fazalar soni yagona bosqich, uch fazali, to'rt fazali va beshtafazasi. Har bir bosqichda o'rnatilishi mumkin bo'lgan mis panjaralari bir qator qatorga, ikki qator va to'rt qatorga bo'linadi.

- Issiqlik shidik naycha

- Yuqori voltli izolyator

- Kam voltli izolyator

Elektr antumbari nima?

Blog | Yangiliklar xodimi | 162024 yil may

Elektruparanlar paneli - bu elektr energiyasidan samarali va xavfsiz tarzda elektr energiyasidan samarali va xavfsiz tarzda tarqatish uchun ishlatiladigan o'tkazuvchan metall bar. Quvvat taqsimlash tizimida markaziy tugun sifatida harakat qilish, u minimal energiya yo'qotilishi bilan yuqori energiya yo'qotadi, uni elektr infratuzilmasining asosiy tarkibiy qismiga aylantiradi.

Yuqori o'tkazuvchanligi, termal bardoshi va mexanik kuchlari tufayli elektr tokilar, podstansiyalar, qayta tiklanadigan energiya tizimlari va elektr transport vositalarini zaryadlash stantsiyalarida keng qo'llaniladi. Uning dizayni va ishlashi ko'pincha IEC 62271 (yuqori voltli almashtirish va boshqarish uchun) va Ieee C37 kabi (quvvat almashtirish uchun) global muvofiqlik va operatsion xavfsizligini ta'minlash.

Elektr avtobuslari turli xil shakllarda, laminatsiyalangan yoki modulli turli xil ekologik va xavfsizlik talablariga javob beradigan modulda mavjud. An'anaviy kabellar bilan taqqoslaganda, ular ko'proq ixcham tartibni qo'llab-quvvatlaydilar, tarqalishning eng yaxshi tarqalishini va texnik xizmatni osonroq, ayniqsa yuqori yuk yoki bo'shliqli qurilmalarda.

Sanoat kuchlari panjaralaridan Quyosh panjaralari va elektr harakatchanligi uchun elektr tog 'sig'imi, elektr barsuvchilari ishonchli, samarali va odatiy energiyani taqsimlashda muhim rol o'ynaydi.

Mundarija

AlmashtirmoqElektr avtobusbari nimadan yasalgan?

Elektrotexnika avtobuslari asosan alyuminiy yoki misdan yasalgan. Mis va alyuminiy elektr energiyasini yuqori elektr o'tkazuvchanligi tufayli jihoz davomida elektr energiyasining samarali o'tishini ta'minlash uchun juda yaxshi materiallardir. Mis odatda yuqori elektr o'tkazuvchanligi va korroziyaga chidamliligi sababli yuqori oqimlarga muhtoj bo'lgan dasturlarda foydalaniladi. Alyuminiy arzon, engil va ko'p kamroq bo'lganiga qaramay, ko'p kam bo'lmagan talablarga javob beradio'tkazuvchan.

Elektr antika vositalari ishlab chiqarish jarayoni bir necha bosqichlarni o'z ichiga oladi. Birinchidan, mis yoki alyuminiy material kerakli shaklda va o'lchamga kiradi, keyin shtamp, egilib, burg'ulash kabi jarayonlar orqali kerakli tuzilishga ishlov beriladi. Uning ishlashi va chidamlilikini oshirish uchun, kolleksiya va korroziyaga xalaqit berish uchun ko'pincha qalay yoki nikel pin yoki nikel artizasi. Ushbu muolajalar bir xil sharoitlarda Busbarning barqarorligi va uzoq umrini ta'minlaydi.

Amaliyotda elektr energiyasini ulash va tarqatish uchun elektr energiyasini almashtirish va tarqatish uchun elektr energiyasini almashtirish va tarqatish uchun elektr energiyasini elektr taxtasi, podstansiyalar va turli sanoat sharoitlarida ishlatiladi. Ularning dizayni va ishlab chiqarish tizimning xavfsizligi va samarali ishlashini ta'minlash uchun qat'iy xalqaro standartlarga rioya qilish kerak. Yangi energiya texnologiyalarini rivojlantirish bilan, shuningdek, yashil energiyani yuqish va tarqatishni qo'llab-quvvatlovchi sohalarda, masalan, quyosh va shamol energiyasi kabi tobora ko'payib bormoqda.

Umuman olganda, To'plamlar uchun materiallar va ishlab chiqarish jarayonlarini tanlash uning ishlashi va ishonchliligi uchun juda muhimdir. Mis va alyuminiy asosiy materiallar sifatida, ilg'or ishlov berish texnologiyasi orqali, kollyatsion tizimlarda Usbarni almashtirib bo'lmaydigan va muhim rol o'ynaydi. An'anaviy quvvat tizimlari yoki yangi energiya manbalari, elektrotexnika vositalari elektr energiyasini samarali va xavfsiz uzatishni ta'minlashning asosiy tarkibiy qismidir.

Turli xil elektruta panellari

Elektr avtobuslari turli xil dastur stsenariylari va ehtiyojlari uchun mos keladigan materiallar va xususiyatlarga ko'ra turli xil turlarga qarab toifalash mumkin. Quyida ba'zi bir oddiy kolonna turlari va ularning xususiyatlari mavjud:

Mis Bubar

Mis Busbars elektr tokuqlari va korroziya qarshiligi uchun elektr tizimlarida keng qo'llaniladi. Mis yuqori o'tkazuvchanligiga ega, chunki bu juda yuqori hozirgi transfer va past qarshilik talab qilinadigan dasturlarda ayniqsa muhimdir. Bundan tashqari, mis to'lqinbarlari yuqori mexanik kuchga ega va yuqori mexanik stressga bardosh bera oladi.

Alyuminiy Busbar

Alyuminiy Busbars engil vazn va arzon narxlar tufayli mis avtobuslar uchun alternativa. Garchi alyuminiy misga nisbatan bir oz pastroqlikni oshirib yuboradi, shunga o'xshash elektr tarmog'iga kesishma effektivi tobora kengayib borishi bilan erishish mumkin. Alyuminiy Busbars katta bino va elektr infratuzilmasi kabi og'irlik va xarajatlarni sezgir loyihalar uchun mos keladi.

Tin bilan qoplangan avtobus

Tinni shudgorlash kolonnasi - bu korroziyaga chidamliligi va lehimchilikni kuchaytirish uchun qalay bilan qoplangan alyuminiy oralig'i. Tinni plitkalash oksidlanishning oldini oladi, elektrustanlar panelining xizmatini kengaytiradi va aloqadorlik bilan aloqa qiladi. Ushbu turdagi avtobuslar bar qismida yuqori barqarorlik talab qilinadigan elektr jihozlarida ishlatiladi.

Kumush qoplangan avtobuzi

Kumush bilan qoplangan kolleksiya - bu o'tkazuvchanlik va korroziyaga chidamlilikni yanada oshirish uchun kumush qatlam bilan qoplangan mis kolleksiya. Kumushning o'tkazuvchanligi misdan yuqori, uni yuqori aniqlikdagi elektron uskunalar va juda yuqori darajada o'tkazuvchanlikni talab qiladigan yuqori darajadagi elektron uskunalar va yuqori chastotali tobora.

Izolyatsiyalangan avtobuzi

Izolyatsion elektr barlarining qisqa tutqichlari va elektrotexnikalarning oldini olish uchun izolyatsion materiallar qatlami bilan ijro etuvchi vositalar panjarali vositalari. Ushbu turdagi elektrutalar paneli elektr tarqalish kabinetlari, kommutali shkaflar va yuqori darajadagi xavfsizlikni talab qiladigan boshqa dasturlarda keng qo'llaniladi. Izolyatsion materialni tanlash turli burchaklar va foydalanish muhitiga mos ravishda sozlanishi mumkin.

Moslashuvchan avtobuslar paneli

Moslashuvchan avtobuslar bardali mis yoki alyuminiy simlardan yasalgan, yaxshi moslashuvchanlik va tebranishga qarshi ta'sirli. Bu shamol turbinalari va uyali elektr stantsiyalari kabi tez-tez harakatlanish yoki tebranishni talab qiladigan quvvat tizimlari uchun mos.

O'ng elektr energiyasini tanlash, hozirgi uzatilish talablari, xarajatlar va atrof-muhit sharoitlari kabi omillarni har tomonlama ko'rib chiqish talab etiladi. Elektrupartambarlar to'lanadigan oqilona tanlash va dizayni nafaqat energiya tizimining samaradorligini oshirishi, balki uning uzoq muddatli barqaror ishlashini ta'minlaydi.

Avtobuslardan foydalanishning afzalliklari

Birinchidan, elektrotexnika jamsubarlari yuqori elektr o'tkazuvchanligiga ega, bu energiya yo'qotishni kamaytiradi. Buning sababi, Busbarning katta kesishgan maydoni, bu chidamlilikning past zichligiga olib keladi, bu qarshilikni kamaytiradi. Bundan tashqari, mis va alyuminiy, o'tkazuvchan materiallar kabi mukammal elektr o'tkazuvchanligiga ega, bu esa uzatma energiya samaradorligini oshiradi.

Ikkinchidan, elektrotexnika avtobuslari ixcham va ozgina joy egallaydi. Kompektiv quvvat tizimlarida elektrutalar panellaridan foydalanish simlarni soddalashtirish va kesish mumkin, masalan, tarqatish kabinetlari va podstansiyalar kabi bo'sh joylarda juda muhimdir. Uning modulli dizayni shuningdek, o'rnatish va texnik xizmatni osonlashtirish va tezroq qiladi.

Bundan tashqari, To'sufning yuqori mexanik kuchi katta ta'sir va mexanik stressga bardosh berishi mumkin. Bu Busbarni energiya tizimida yuqori darajadagi xavfsizlik va ishonchlilikka ega, quvvat tizimining barqaror ishlashini ta'minlamasligi uchun yuqori darajadagi xavfsizlik va ishonchlilikni ta'minlaydi.

Nihoyat, Busbarda ham issiqlik tarqalishining yaxshi ishlashi yaxshi. Uning katta sirt maydoni tufayli u ishlash paytida ishlab chiqarilgan issiqlikni samarali ravishda tarqatishi, haddan tashqari qizib ketishining oldini olish, shu bilan xizmat ko'rsatish uchun xizmat ko'rsatish muddati.

Xulosa qilib aytganda, elektr energiyasining yuqori elektr o'tkazuvchanligi, kompakt tuzilishi, yuqori issiqlik muhandisligi uchun samarali, xavfsiz va ishonchli echim tufayli elektr toki bo'shlig'ining ajralmas va muhim qismiga aylandi.

Busbars qanday ishlaydi?

Elektr energiyasining asosiy funktsiyasi elektr energiyasini elektr energiyasini taqsimlash tizimidagi elektr energiyasini samarali taqsimlashni ta'minlash uchun jihozlarni tarqatish tizimiga o'tkazishdir. Ularning yuqori mahkumoti va kam qarshilik ko'rsatgani sababli, Busbares katta energiya yo'qotadigan katta oqimlarni uzatishi mumkin. Tarqatish kabinetlari, kollektsion elektr ulanishini ta'minlash uchun odatda o'rnatilishi, payvandlash yoki qisish bilan o'rnatiladi. Busbar tizimlarining ishonchliligi va xavfsizligini ta'minlash uchun yuk kabi omillarDizayn vaqtida joriy, harorat ko'tarilishi, qisqa tutashuv oqimi va mexanik kuchni ko'rib chiqish kerak. Elektr avtobus tizimlari odatda tizimning ishonchliligi va operatsion samaradorligini oshirish bo'yicha elektr stantsiyalari, elektr stantsiyalari va yirik sanoat komplekslari kabi joylarda qo'llaniladi.

Busbar nima uchun ishlatiladi?

Busbars keng qamrovli dasturlarda qo'llaniladi, shu jumladan:

- Quvvatni taqsimlash panellari: Turar-joy, tijorat va sanoat sozlamalarida samarali energiya taqsimlashni ta'minlash.

- Siljitmoq: Elektr qatnovchi tarkibidagi turli komponentlar o'rtasida ishonchli ulanishni ta'minlash.

- Podstansiyalar: Elektr podstansiyalarida energiya taqsimlash va nazoratni osonlashtirish.

- Ma'lumot markazlari: Serverlar va boshqa tanqidiy uskunalarga ishonchli quvvatni ishonchli taqsimlashni ta'minlash.

- Avtomobil va transport: Quvvatni samarali taqsimlash uchun elektr transport vositalari va transport tizimlarida ishlatiladi.

Elektr tizimidagi To'plambar nima?

Elektr tizimida elektr ta'minotbarida turli xil tarkibiy qismlarni ulash va barqaror va samarali elektr oqimini ta'minlash uchun elektr tarmog'ini ko'tarish uchun fond sifatida ishlaydi. Bu energiya zavodlari, tijorat binolari va infratuzilmasi va infratuzilmasi loyihalarida muhim energiya taqsimoti zarur bo'lgan tizimlarning tanqidiy elementidir.

Kabellar va Busbars

Elektrotexnika, kabellar va kollektsiyalarda elektr energiyasini o'tkazishning ikkita keng tarqalgan usulidir, ularning har biri noyob afzallik va dasturlar mavjud.

Kabellar:

- Afzalliklari: Turli xil kuchlanishlar uchun mos (pastdan yuqori) uchun mos keladigan ixtisoslashgan vositalarsiz juda moslashuvchan, juda moslashuvchan.

- Kamchiliklar: Yuqori oqimlar bilan haddan tashqari qizib ketishga moyil, yuqori zichlikli simlar, murakkab va mehnatga intensiv parvarishlashda ko'proq joy egallaydi.

Avtobuslar:

- Afzalliklari: Yuqori oqimlar uchun juda yaxshi issiqlik tarqalishi, ixcham dizayni, eng zichlik uchun kamchilikni aniqlash va ta'mirlash, yuqori zichlik uchun ideal.

- Kamchiliklar: Ixtisoslashgan ko'nikmalar va uskunalarni talab qiladigan murakkab simli yo'llar, kompleks va vaqtni iste'mol qilish vositalari uchun moslashuvchan.

Arizalar:

- Kabellar: Turar-joy, tijorat va umumiy ishlab chiqarish sohalari kabi moslashuvchan simlarga ehtiyoj va iqtisodiy jihatdan samarali echimlar uchun ideal.

- Avtobuslar: Sanoat ob'ektlari va yirik binolar kabi samarali uzatish va oson texnik xizmat ko'rsatishni talab qiladigan yirik loyihalar uchun eng yaxshisi.

Jadval: Kabellar VS Busbars

| O'ziga xos xususiyat | Kabellar | Avtobuslar |

|---|---|---|

| Moslashuvchanlik | Baland | Past |

| O'rnatishning qiyinligi | Oddiy | Murakkab |

| Issiqlikni buzish | Kambag'al | Juda yaxshi |

| Kosmik kasb | Katta | Kichik |

| Texnik xizmat ko'rsatish | Baland | Past |

| Boshlang'ich narx | Past | Baland |

| Voltaj diapazoni | Yuqori kuchlanish uchun past | Asosan yuqori kuchlanish uchun o'rtacha |

| Kerakli dasturlar | Turar-joy, tijorat, sanoat | Sanoat, yirik binolar |

To'plamlardagi FAQ

Savol: Wrat mens trt tshilmoqpechkamental voyaga yettirmoqoltaginat ratmenngina favquloddaor busbars?

Javob: voltaginat ratmennginas favquloddaor busbars voyaga yettirmoqarshilmoq shilmoqmendumtlshilmoq dumtpechkatndummenngina on trt apechkapechkalmentatmenon andum dumtsmenginan. Trtshilmoq tan randumlt voyaga yettirmoqoltaginats favquloddaroshodlik loshilmoq–voyaga yettirmoqoltaginat sshilmoqsttshodliks to rmenginar–voyaga yettirmoqoltaginat apechkapechkalmentatmenons.

Savol: Avtobusbarni an'anaviy simlardan foydalanishning afzalliklari qanday?

Javob: Busbars yuqori samaradorlik, kosmik omonat, moslashuvchanlik, xavfsizlik va o'rnatish qulayligi ta'minlanadi.

Savol: Busbars qanday qilib qayta tiklanadigan energiya tizimlarida ishlatiladi?

Javob: Umumiy elektr energiyasini yig'ish va tarqatish uchun quyosh va shamol energiyasining energiya tizimlarining muhim tarkibiy qismidir. Ular elektr manbai va yuklash yoki yuk orasidagi oqim oqimining ishonchli va samarali yo'lini taqdim etadilar.

Savol: Busbars sozlashi mumkinmi?

Javob: Ha, Busbars turli xil tarmoqlar uchun mos keladigan echimlarni taklif qilish uchun maxsus dastur talablariga javob berish uchun sozlanishi mumkin.

Savol: To'plambar magistral tizimi nima?

Javob: To'plambar magistraling tizimi - bu himoya uyiga kirgan kolulyar tizimdir. Bu moslashuvchan va oson tarmog'ini tarqatishning echimini ta'minlaydi.

Ko'proq ma'lumot olishni xohlaysizmi? Bu yerni bosing Mahsulot tafsilotlarini ko'rish uchun!

--- OXIRI ---

Ma'lumot

Mahsulot

- Busbarni qo'llab-quvvatlash

Avtobuslar panori uchun tanlov uchun avval sizning mis baringiz spetsifikatsiyasini tasdiqlang. Tasdiqlanganidan so'ng, sizning avtobuslar panelingiz qancha bosqichda, qancha pog'onalar panjarasi va har bir faza bar va boshqa bir faza bar orasidagi masofa va boshqa faza masofasi qanday fazali faza masofasi borligini tasdiqlang. Sizga kerak bo'lgan o'lcham bo'yicha turni tanlang. Umumiy naslchilik 55, 80, 100, 110, 130, 130, 160, 170, 175 va 180 (birlik: mm). Fazalar soni yagona bosqich, uch fazali, to'rt fazali va beshtafazasi. Har bir bosqichda o'rnatilishi mumkin bo'lgan mis panjaralari bir qator qatorga, ikki qator va to'rt qatorga bo'linadi.

- Issiqlik shidik naycha

Issiqlik shiddatli naychadir - bu qizdirilgan issiqlik va issiqlik sezgir plastik qisqichni, u qizdirilganda diametri. U kabellar, simlar va shlanglarni izolyatsiya qilish va himoya qilish uchun ishlatiladi. Issiqlik shidirlash naychasini kabel ulagichlari uchun qoplash sifatida ishlatilishi mumkin. Isitilganda, naycha ulagich atrofida mahkam siqiladi, suv o'tkazmaydigan va korroziyali muhr yaratadi. Issiqlik shiddatli naychali elektr izolatsiyasini, mexanik himoya, atrof-muhitni muhrlash va nochor yordamni ta'minlaydi. Bizning issiqlik shidir-shuvli naychamiz yolg'iz vaIkkita devor naychalari turli xil dasturlarga, shu jumladan orqa tugatish ulagich muhrlash, buzish va ulagichga ulagichga o'tish uchun mo'ljallangan. Bu lenta, kalıplama yoki pot-pot-pot-ichish uchun ishonchli alternativa. Bundan tashqari, bizning qisqarish naychamiz yuqori sifatli materiallardan iborat bo'lib, ular yuqori sifatli himoya va izolyatsiyani ta'minlaydi. Biz sizning ehtiyojlaringiz uchun mukammal issiqlik shidirpubik naychasini topishingiz uchun turli xil o'lcham va ranglarni taklif etamiz.

- Yuqori voltli izolyator

Yuqori kuchlanish izolyatorlari yuqori voltli dasturlarda muhim tarkibiy qismdir. U odamlarni va uskunalarni yuqori kuchlanish elektr energiyasidan himoya qilish uchun mo'ljallangan. Elektr qurilishi, elektr stantsiyalari, podstansiyalar va izolyatsiyani talab qiladigan boshqa joylar uchun. Elektr izoli - bu elektronlarning erkin oqimiga xalaqit beradigan material. Ishonchlilik, mavjudlik va quvvat zichligi barcha zamonaviy elektr energiyasi va elektr tarmoqlari uchun juda muhimdir.

- Kam voltli izolyator

Kam kuchlanish izolyatorlari har qanday elektr tizimining ajralmas qismidir. Unda elektr jihozlari va ayirboshlash vositalarini himoya qilish uchun zarur va samarali izolyatsiyani ta'minlaydi. U odamlarni va uskunalarni shikastlanish yoki elektr tizimlarida ortiqcha yuklar tufayli shikastlash yoki zarardan himoya qilish uchun ishlatiladi. Kam kuchlanish izolyatorlari yuqori sifatli materiallardan tayyorlanadi va bardoshli. Gaitan past kuchlanishli qavslar, iqtisodiy va mexanik bilan samarali izolyatorlarning to'liq liniyasini taklif etadiparametr barqarorligi va juda yuqori oqishning juda yuqori chidamliligi.

Busbar qisqichbaqasi

- MD Busbarni qo'llab-quvvatlash

MD avtobusni qo'llab-quvvatlash To'plamli izolyator BMC / SMC-dan tayyorlanadi, u bir fazali, uch fazali, to'rt bosqichli va besh bosqichli avtobusni qo'llab-quvvatlash uchun ishlatiladi. U past kuchlanishli taqsimlash liniyalari va aloqa liniyalari uchun ishlatiladi va tarqatish qutisi, kommutatsiya qutisi, inverter va yashil elektr ta'minoti kabi elektr dasturlarida keng qo'llaniladi.

- El Bubarni qo'llab-quvvatlash

Marmar Busbar Clamp, tashqi savdo turi

- Bir qator Usbarni qo'llab-quvvatlash

Oq Busbar qisqich, kichik o'lcham, qulay saqlash va moslashuvchan kombinatsiya

Kam voltli izolyator

- Sm izolyator

Temirlashtirishni elektr energiyasidan foydalanishga nisbatan qo'llanilishi mumkin

- MNS izolyator

Yuqori kuch izolyator, yuqori kuch va kattaroq kiritilishi bilan ko'proq qo'llab-quvvatlashi mumkin

- SB izolyator

Yangi energiya izolyator kuchli barqarorlik va kichik hajmdagi elektr transport vositasi va zaryadlash qoziq kabi yuqori quvvatli muhitga mos keladigan muhitga mos keladi

- En izsatsiya

- Lik izi

- Dly izolyator

- Seyolylagich

- Mg izolyator

- Pt izolyator

Oddiy sim ulanishiga mos keladigan oddiy izolyator

- CT izolyator

Elektron pochta: [email protected]

Elektron pochta: [email protected]

№ 20 Lingyun yo'li, dongfeng

№ 20 Lingyun yo'li, dongfeng

Sanoat zonasi, liushi shahri, yuqish

Shahar, Jejian viloyati

G'altak

Sho'x

© Copyright 2024 Xitoy Gaitan elektromexanik texnologiya Co., Ltd. Barcha huquqlar himoyalangan.Qo'llab-quvvatlash: Junj Maxfiylik siyosati