Why MD Busbar Supports Are Widely Used in Distribution Boards

介绍

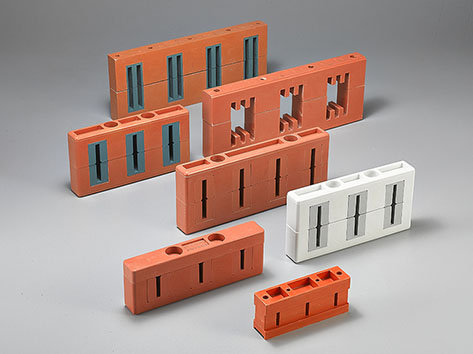

Distribution boards play a critical role in power distribution systems by safely routing electrical energy to multiple circuits. Inside these boards, busbars must be securely supported, precisely aligned, and properly insulated. MD busbar supports have become a popular choice in distribution boards due to their balanced performance, compact design, and reliable insulation characteristics.

The Role of Busbar Supports in Distribution Boards

Busbar supports provide both mechanical and electrical functions. They hold busbars firmly in position, maintain insulation distances between phases, and help the system withstand operational and fault-related stresses.

In distribution boards, space is limited, installation efficiency is critical, and safety requirements are strict. These conditions demand a busbar support solution that is compact, durable, and easy to install—exactly where MD busbar supports excel.

Compact Design for Space-Efficient Panels

One of the main reasons MD busbar supports are widely adopted is their compact and standardized design. Distribution boards often require high circuit density within a limited enclosure size. MD supports allow multiple busbars to be mounted securely while minimizing the overall footprint.

This compactness helps panel builders:

Optimize internal layout

Improve airflow and heat dissipation

Achieve cleaner and more organized wiring

Reliable Mechanical Strength and Stability

During normal operation and especially under short-circuit conditions, busbars are subjected to significant electrodynamic forces. MD busbar supports are designed to provide sufficient mechanical strength to resist these forces without deformation or displacement.

Their rigid structure ensures:

Stable busbar positioning

Reduced vibration and movement

Long-term mechanical reliability

This stability is essential for maintaining electrical safety throughout the service life of the distribution board.

Excellent Insulation Performance

Electrical insulation is a critical requirement in distribution boards. MD busbar supports are typically manufactured from high-performance insulating materials such as DMC or BMC, which offer:

High dielectric strength

Strong resistance to tracking and arcing

Stable performance under elevated temperatures

These properties help prevent phase-to-phase and phase-to-ground faults, even in demanding operating environments.

Simplified Installation and Maintenance

MD busbar supports are designed with standardized dimensions and mounting methods, making them easy to install in various distribution board designs. Fewer individual components are needed compared to single busbar supports, which reduces assembly time and installation errors.

For maintenance, their clear structure allows:

Easy visual inspection

Quick busbar replacement or modificationReduced downtime during servicing

Compatibility with Different Busbar Configurations

MD busbar supports can be used with copper or aluminum busbars and support various phase configurations. This versatility makes them suitable for a wide range of distribution board designs across residential, commercial, and industrial applications.

符合行业标准

Many MD busbar supports are designed to meet international standards such as IEC and UL. Compliance with these standards ensures that the supports meet recognized safety and performance requirements, making them suitable for global markets.

Cost-Effective Solution for Panel Builders

By combining mechanical strength, insulation reliability, and installation efficiency, MD busbar supports offer a cost-effective solution for distribution board manufacturers. Reduced assembly time, lower component count, and long service life contribute to overall cost savings.

结论

MD busbar supports are widely used in distribution boards because they provide an optimal balance of compact design, mechanical stability, insulation performance, and ease of installation. Their standardized structure and reliable performance make them a practical choice for modern power distribution systems.

Selecting the right MD busbar support helps ensure safety, efficiency, and long-term reliability in distribution board applications.

- - 结尾 - -

邮箱:

邮箱: 东风市凌云路20号

东风市凌云路20号