电力母线是一种导电金属棒,通常由铜或铝制成,用于在电路中高效、安全地分配电力。作为配电系统中的中心节点,它能够以最小的能量损失处理高电流传输,使其成为电力基础设施中的关键组件。

由于其高导电率、热弹性和机械强度,电动母线广泛应用于配电盘、变电站、可再生能源系统和电动汽车充电站。其设计和性能通常遵循 IEC 62271(针对高压开关设备和控制设备)和 IEEE C37(针对电力开关设备系统)等国际标准,确保全球合规性和操作安全。

电力母线有多种形式(绝缘母线、层压母线或模块化母线),以满足不同的环境和安全要求。与传统电缆相比,它们支持更紧凑的布局、更好的散热和更容易的维护,特别是在高负载或空间受限的安装中。

从工业电网到太阳能光伏应用和电动汽车,电动母线在提供可靠、高效且符合标准的配电方面发挥着至关重要的作用。

电动母线是由什么制成的?

电气母线主要由铝或铜制成。铜和铝具有高导电性,是确保电能在整个系统中有效通过的优异材料。由于铜具有很强的导电性和耐腐蚀性,因此通常用于需要高电流的应用。铝价格便宜、重量轻,并且在许多中低电流应用中表现良好,尽管其重量稍轻导电。

制造电气母线的过程涉及几个步骤。首先,将铜或铝材料切割成所需的形状和尺寸,然后通过冲压、弯曲和钻孔等工艺加工成所需的结构。为了增强其性能和耐用性,母线表面通常镀锡或镀镍,以防止氧化和腐蚀。这些处理保证了母线在各种恶劣环境下的稳定性和长寿命。

在实践中,电气母线用于配电盘、变电站和各种工业设施中以连接和分配电能。其设计和制造需要遵守严格的国际标准,以确保系统的安全和高效运行。随着新能源技术的发展,电动母线也越来越多地应用于太阳能、风电等领域,支撑绿色能源的输配电。

总体而言,母线的材料选择和制造工艺对其性能和可靠性至关重要。以铜、铝为主要材料,通过先进的加工技术,使母线槽在配电系统中发挥着不可替代的重要作用。无论是在传统电力系统还是新能源中,母线都是保证电力高效、安全传输的关键部件。

不同类型的电动母线

电动母排根据材质和特性可分为多种类型,适合不同的应用场景和需求。以下是一些常见母线类型及其特点:

来源: 亚马逊

来源: 亚马逊

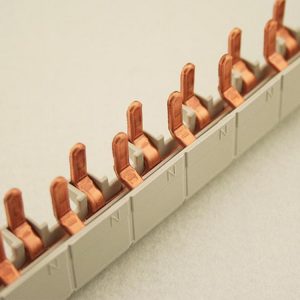

铜母线

铜母线以其优良的导电性和耐腐蚀性广泛应用于电力系统。由于铜具有高导电性,因此在需要高电流传输和低电阻的应用中尤其重要。此外,铜母线具有较高的机械强度,能够承受较高的机械应力。

铝母线

铝母线由于重量轻、成本低而成为铜母线的替代品。虽然铝的导电率比铜稍低,但通过增加截面积可以达到相同的传输效果。铝母线适用于对重量和成本敏感的项目,例如大型建筑和电力基础设施。

镀锡母线

镀锡母排是在铜或铝母排上涂上一层锡,以增强其耐腐蚀性和可焊性。镀锡可防止氧化,延长电汇流条的使用寿命,提高接触可靠性。此类母线常用于稳定性要求较高的电气设备中。

镀银母排

镀银母排是在铜母排上镀上一层银,以进一步增强其导电性和耐腐蚀性。银的导电率比铜高,适合用于需要极高导电率和耐用性的高精度电子设备和高频电路。

绝缘母线

绝缘母线在导电母线上覆盖一层绝缘材料,以防止短路和触电事故。该类型电气母线广泛应用于配电柜、开关柜以及其他对安全性要求较高的场合。绝缘材料的选择可以调整,以适应不同的电压等级和使用环境。

柔性母线

柔性母线由多股铜线或铝线绞合而成,具有良好的柔韧性和抗振动性能。适用于需要频繁运动或振动的电力系统,如风力发电机、移动电站等。

选择合适的电气母线需要综合考虑电流传输要求、成本和环境条件等因素。合理选择和设计电力母线不仅可以提高电力系统的效率,而且可以保证其长期稳定运行。

使用母线的优点

首先,电气母线具有高导电性,有效减少能量损失。这是因为母线的横截面积较大,导致电流密度较低,从而降低了电阻。另外,铜和铝作为导电材料,具有优异的导电性能,进一步提高了传输效率。

其次,电气母线结构紧凑,占用空间小。在复杂的电力系统中,使用电动母线可以简化接线并减少占地面积,这对于配电柜和变电站等空间有限的地方尤其重要。其模块化设计也使安装和维护变得更容易、更快捷。

此外,母线机械强度高,可承受大电流冲击和机械应力。这使得母线在电力系统中具有高度的安全可靠性,不易发生故障,保证电力系统的稳定运行。

最后,母排还具有良好的散热性能。由于其表面积大,可以有效散发运行过程中产生的热量,防止过热,从而延长设备的使用寿命。

综上所述,电力母线以其导电率高、结构紧凑、机械强度高、散热性能好等优点成为电力系统中不可缺少的重要组成部分,为现代电力工程提供了高效、安全、可靠的解决方案。

母线如何工作?

电力母线的主要作用是在配电系统中的设备之间传输电能,保证高效配电。由于母线具有高导电性和低电阻,因此可以传输大电流而能量损失很小。在配电柜中,母线通常通过螺栓连接、焊接或夹紧来安装和固定,以确保安全的电气连接。为保证母线系统的可靠性和安全性,负载等因素设计时必须考虑电流、温升、短路电流和机械强度。电动母线系统通常用于数据中心、发电厂和大型工业综合体等场所,用于管理和分配电力,同时提高系统可靠性和运行效率。

母线有什么用?

母线应用广泛,包括:

- 配电盘:确保住宅、商业和工业环境中的高效配电。

- 开关柜:在电气开关设备中的不同组件之间提供可靠的连接。

- 变电站:促进变电站的配电和控制。

- 数据中心:确保服务器和其他关键设备的可靠配电。

- 汽车和交通:用于电动汽车和运输系统,实现高效配电。

什么是电气系统中的母线?

在电力系统中,电力母线充当配电的骨干,连接各个部件并确保电力稳定高效地流动。在工业厂房、商业建筑和基础设施项目等需要可靠配电的系统中,它是一个关键元件。

电缆与母线

在电气工程中,电缆和母线是两种常见的导电方法,各自具有独特的优点和应用。

电缆:

- 优势:高度灵活,无需专用工具即可轻松安装,适用于各种电压(从低到高)。

- 缺点:散热差,大电流容易过热,高密度布线占用空间大,维护复杂、劳动强度大。

母线:

- 优势:散热优良,适合大电流,设计紧凑,更容易故障检测和修复,非常适合高密度布线。

- 缺点:灵活性较低,不适合复杂的布线路径,安装复杂且耗时,需要专门的技能和设备,初始成本较高。

申请:

- 电缆:非常适合灵活布线需求和经济高效的解决方案,例如住宅、商业和一般工业用途。

- 母线:最适合需要高效传输和易于维护的大型项目,例如工业设施和大型建筑。

表:电缆与母线

| 特征 |

电缆 |

母线 |

| 灵活性 |

高的 |

低的 |

| 安装难度 |

简单的 |

复杂的 |

| 散热 |

贫穷的 |

出色的 |

| 太空占领 |

大的 |

小的 |

| 维护难度 |

高的 |

低的 |

| 初始成本 |

低的 |

高的 |

| 电压范围 |

低电压到高电压 |

主要是中高压 |

| 适合的应用 |

住宅、商业、工业 |

工业、大型建筑 |

母线常见问题解答

问:W小时一个t 我s t小时e typ我c一个我 v哦我t一个克e r一个t我n克 f哦r 乙你s乙一个rs?

答:V哦我t一个克e r一个t我n克s f哦r 乙你s乙一个rs v一个ry w我de我y depend我n克 哦n t小时e 一个pp我我c一个t我哦n 一个nd des我克n. t小时ey c一个n 小时一个nd我e v哦我t一个克es fr哦米 我哦w–v哦我t一个克e syste米s t哦 小时我克小时–v哦我t一个克e 一个pp我我c一个t我哦ns.

问:与传统布线相比,使用母线有什么好处?

答:母线提供更高的效率、节省空间、灵活性、安全性和易于安装。

问:母线如何用于可再生能源系统?

答:母线是太阳能和风能系统中用于收集和分配所产生电力的重要组件。它们为电源和电网或负载之间的电流提供可靠且高效的路径。

问:母线可以定制吗?

答:是的,母线可以定制以满足特定的应用要求,为不同行业提供量身定制的解决方案。

问:什么是母线槽系统?

答:母线槽系统是一种预制模块化系统,由封闭在保护外壳中的母线组成。它提供了灵活且易于扩展的配电解决方案。