Types of Wiring Ducts: Slotted, Solid, and Flexible Explained

Блог | Рэдакцыя | студ 21,2026

Уводзіны

Каналы электраправодкі are essential components in electrical cabinets and control panels, helping organize cables, improve safety, and simplify maintenance. With multiple designs available, choosing the right type of wiring duct can significantly impact panel performance and efficiency. This article explains the three main types of wiring ducts—slotted, solid, and flexible, highlighting their structures, advantages, and typical applications.

What Is a Wiring Duct?

А wiring duct (also known as a wire duct or cable duct) is a cable management channel used to route and protect electrical wires inside enclosures. Wiring ducts help prevent cable damage, reduce clutter, and ensure a clean, professional panel layout.

They are commonly manufactured from:

PVC

Halogen-free plastic

Metal (for special environments)

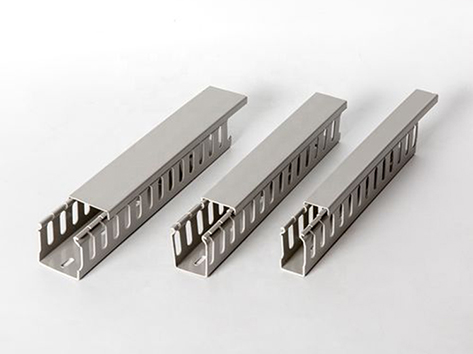

Slotted Wiring Duct

Structure and Design

Slotted wiring ducts feature open slots or fingers along both side walls. These slots allow cables to be easily inserted or removed at any point along the duct length.

Асноўныя перавагі

Easy cable routing and modification

Improved airflow and heat dissipation

Clean and organized wiring layout

Faster installation and maintenance

Тыповыя прымянення

Industrial control cabinets

PLC and automation panels

Low-voltage distribution boards

Slotted wiring ducts are the most widely used type due to their flexibility and ease of use.

Solid Wiring Duct

Structure and Design

Solid wiring ducts have fully enclosed side walls without slots. Cables enter and exit only at the ends or through custom cut-outs.

Асноўныя перавагі

Maximum cable protection

Reduced dust and debris entry

Cleaner exterior appearance

Тыповыя прымянення

Areas requiring high mechanical protection

Environments with dust or contamination

Panels where wiring changes are infrequent

Solid wiring ducts are often chosen when protection and appearance are higher priorities than frequent wiring access.

Flexible Wiring Duct

Structure and Design

Flexible wiring ducts вырабляюцца з bendable or corrugated materials, allowing them to adapt to curved or irregular paths.

Асноўныя перавагі

Excellent flexibility for tight or complex spaces

Absorbs vibration and movement

Easy installation in dynamic environments

Тыповыя прымянення

Moving equipment and machinery

Door-mounted components

Applications with vibration or repeated motion

Flexible wiring ducts are ideal when rigid ducting is impractical.

Comparison of Wiring Duct Types

| Асаблівасць | Slotted Duct | Solid Duct | Flexible Duct |

| Cable Access | Выдатна | Limited | Добра |

| Protection Level | Сярэдні | Высокі | Сярэдні |

| Гнуткасць | Нізкі | Нізкі | Высокі |

| Installation Speed | Fast | Умераны | Fast |

| Typical Use | Control panels | Protected areas | Dynamic wiring |

How to Choose the Right Wiring Duct

When selecting a wiring duct, разгледзім:

Cable quantity and size

Frequency of wiring changes

Environmental conditions (dust, heat, chemicals)

Panel layout and available space

Safety and compliance requirements

In many control cabinets, slotted wiring ducts are used as the primary solution, with solid or flexible ducts applied in specific areas as needed.

Заключэнне

Understanding the differences between slotted, solid, and flexible wiring ducts helps ensure efficient cable management and long-term system reliability. Each type offers unique advantages, making it suitable for different panel designs and operating conditions.

By choosing the right wiring duct type, panel builders and engineers can improve safety, organization, and maintenance efficiency in electrical and automation systems.

FAQ

What is the most commonly used type of wiring duct?

The slotted wiring duct is the most commonly used type in electrical control panels. Its open-slot design allows easy cable insertion, routing, and future modifications, making it ideal for automation and low-voltage distribution systems.

When should I choose a solid wiring duct?

Solid wiring ducts are best used when maximum cable protection is required or when the environment contains dust, debris, or contaminants. They are suitable for panels where wiring changes are infrequent and a clean exterior appearance is important.

What applications are flexible wiring ducts used for?

Flexible wiring ducts are commonly used in:

Moving machinery

Door-mounted panel components

Applications with vibration or repeated motion

Their flexibility helps prevent cable stress and damage in dynamic environments.

What materials are wiring ducts made from?

Wiring ducts are typically manufactured from:

PVC (cost-effective and widely used)

Halogen-free plastics (for enhanced fire safety)

Metal (for extreme mechanical or environmental protection)

Material selection depends on safety standards, temperature, and environmental conditions.

Are wiring ducts flame retardant?

Most industrial wiring ducts are designed to be flame retardant and comply with standards such as UL or IEC. Always verify material specifications and certifications for safety-critical applications.

How do I size a wiring duct correctly?

Wiring ducts should be sized to allow sufficient space for current cables plus future expansion. A common guideline is to use no more than 50–60% of the duct’s internal capacity to maintain airflow and simplify maintenance.

Can different types of wiring ducts be used in the same panel?

Yes. Many control panels use slotted wiring ducts as the main routing system, combined with solid or flexible ducts in specific areas to address protection or movement requirements.

How do wiring ducts improve panel safety?

Wiring ducts reduce cable congestion, prevent insulation damage, improve airflow, and make wiring paths easier to inspect. This helps lower the risk of short circuits, overheating, and maintenance errors.

--- КАНЕЦ ---

© Аўтарскае права China Haitan Electromechanical Technology Co., Ltd., 2024. Усе правы абаронены.ПАДТРЫМКА: JUNJ Палітыка прыватнасці

Адрас электроннай пошты:

Адрас электроннай пошты:  No 20 Lingyun Road, Dongfeng

No 20 Lingyun Road, Dongfeng