Copper Ground Bar Thickness and Current Carrying Capacity Guide

導入

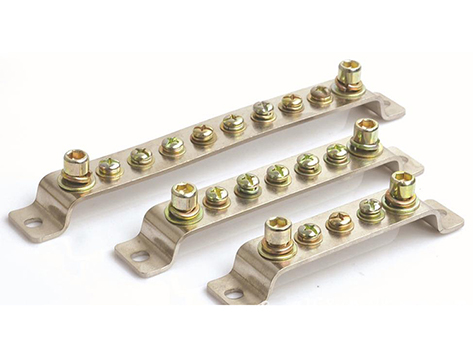

Copper ground bars are critical components in electrical panels and low-voltage distribution systems. They provide a reliable path for fault currents and ensure electrical safety for equipment and personnel. Selecting the correct thickness and current carrying capacity of a copper ground bar is essential for efficient and safe grounding. This guide explains how to choose the right copper ground bar based on thickness, cross-sectional area, and load requirements.

What Is a Copper Ground Bar?

a copper ground bar is a conductive busbar made of copper, used to connect multiple grounding conductors in an electrical panel or system. It provides a single, low-resistance path to the ground, ensuring:

Electrical safety for equipment and personnel

Stable reference potential for the system

Effective dissipation of fault currents

Copper is chosen due to its high electrical conductivity, corrosion resistance, and mechanical strength.

Why Thickness Matters

The thickness of a copper ground bar directly affects:

Current carrying capacity – Thicker bars can safely carry more fault current without overheating.

機械的強度 – Thicker bars provide better durability and support for multiple connected cables.

Voltage drop – Adequate thickness ensures minimal voltage drop across the bar during fault conditions.

Using a bar that is too thin can cause overheating, excessive voltage drop, or even system failure, while over-sizing increases cost unnecessarily.

Copper Ground Bar Current Carrying Capacity

The current carrying capacity of a copper ground bar depends on:

Bar thickness and width (cross-sectional area)

Length of the bar

Number of connected conductors

Ambient temperature

Type of installation (enclosed panel vs open air)

Typical Guidelines

| Copper Bar Thickness | Width | Approx. Cross-Section

(mm²) |

Current Capacity

(A) |

Notes |

| 3 mm | 20 mm | 60 | 100–125 | Light-duty panels |

| 5 mm | 25 mm | 125 | 150–200 | Standard industrial panels |

| 6 mm | 30 mm | 180 | 200~250 | Heavy-duty distribution |

| 8 mm | 40 mm | 320 | 300~400 | High-current applications |

| 10 mm | 50 mm | 500 | 400–500+ | Large industrial or renewable energy panels |

Note: Values are approximate. Always refer to IEC 60947, NEC, or local standards for precise sizing based on temperature, fault current, and installation conditions.

Other Factors Affecting Copper Ground Bar Selection

Tinned vs Bare Copper – Tinned copper resists corrosion in humid or outdoor environments.

Number of Terminations – More connected cables require a thicker or wider bar to prevent localized overheating.

Panel Layout – Ensure sufficient clearance around the bar for heat dissipation.

Fault Current Rating – Check maximum expected short-circuit current to ensure the bar can safely handle it.

インストールのヒント

使用 proper torque on terminal screws to ensure secure connections without damaging the bar.

Avoid sharp bends in the copper bar; keep connections straight for minimal resistance.

Label and color-code ground bars when multiple phases or systems are involved.

For modular panels, ensure bar thickness is compatible with DIN Rail and terminal blocks.

結論

Choosing the correct thickness and current carrying capacity of a copper ground bar is critical for electrical safety, reliability, and long-term performance. By considering cross-sectional area, number of connections, environmental conditions, and expected fault currents, engineers and panel builders can ensure efficient grounding and system protection.

Using standardized guidelines and following IEC, NEC, or UL recommendations ensures that copper ground bars perform reliably in industrial, commercial, and renewable energy applications.

よくある質問

What thickness of copper ground bar should I use for my electrical panel?

The required thickness depends on the current carrying capacity, number of connected cables, and fault current rating. Typical industrial panels use copper bars between 3 mm and 10 mm thickness, with wider bars needed for higher currents or multiple connections.

How does the thickness of a copper ground bar affect current carrying capacity?

Thicker copper ground bars have a larger cross-sectional area, which reduces resistance, minimizes voltage drop, and allows the bar to safely carry higher fault currents without overheating.

Can I use a thin copper bar for heavy-duty applications?

No. Using a bar that is too thin can result in overheating, excessive voltage drop, or damage during a fault. Always calculate current requirements and select a bar thickness that meets or exceeds the maximum expected load.

What is the difference between tinned and bare copper ground bars?

Tinned copper: Offers better corrosion resistance in humid, marine, or outdoor environments.

Bare copper: Provides slightly lower cost and slightly higher conductivity but is more susceptible to oxidation over time.

How do I calculate the current carrying capacity of a copper ground bar?

Consider these factors:

Bar thickness and width (cross-sectional area)

Number of connected conductors

Ambient temperature

Installation type (enclosed panel vs open air)

Refer to IEC, NEC, or UL guidelines for precise sizing.

Can a copper ground bar carry the same current as a conductor?

Copper ground bars are designed for fault and grounding currents, not continuous high-load currents like conductors. Always ensure the bar is sized based on maximum fault current and system requirements, not just continuous operating current.

How should I install a copper ground bar safely?

使用 proper torque on screws to avoid damage

Avoid sharp bends; keep bars straight for low resistance

確保する adequate clearance for heat dissipation

Label bars and terminals for easy identification

Can I use the same copper ground bar for multiple panels?

Yes, but ensure the bar’s thickness and width can handle the combined current and number of connections. Large systems may require multiple bars or busbar interconnections to distribute fault current safely.

- - 終わり - -

© Copyright 2024 China Haitan Electromechanical Technology Co., Ltd. 全著作権所有。サポート:JUNJ プライバシーポリシー

電子メール:

電子メール:  東風市霊雲路20号

東風市霊雲路20号