The Ultimate Guide: busbar insulator and busbar clamp in power distribution cabinet

The Ultimate Guide: busbar insulator and busbar clamp in power distribution cabinet

The stable operation of the power system is inseparable from the perfect coordination of various components, whether it is large components such as distribution cabinets, transformers, or some very inconspicuous small accessories such as busbar clamps and busbar insulators, each component plays an important role and is indispensable.

This blog will take you to understand what busbar insulators and busbar clamps are? What role do they play in the distribution cabinet? Grab your coffee and follow this blog to learn together

What is Busbar Insulators and Busbar Clamps

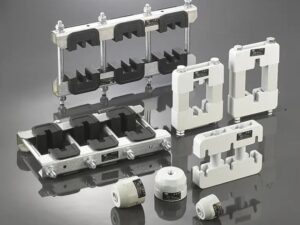

Busbar Insulators are actually a type of insulator. They are mainly used to provide reliable insulation and mechanical support for the busbar in the distribution cabinet. They are used to isolate the busbar from the bracket or other conductors to avoid short circuits. They are usually made of ceramic, epoxy resin or high-performance polymer materials with good insulation. No matter what kind of busbar insulator, you can simply understand it as protecting the busbar in the power system so that it can be safely and stably fixed in the distribution cabinet, providing reliable and stable power transmission to the power system.

Busbar Clamps are a kind of mechanical device made of metal materials such as stainless steel or aluminum alloy, used to connect and fix the busbar and the distribution cabinet. They have good mechanical strength and impact resistance, can firmly fix the busbar, reduce the friction loss caused by loosening of the busbar, and extend its service life. Therefore, busbar clamps can be simply understood as a metal clamp used to fix the busbar, which can effectively prevent the loose connection between the busbar and electrical components in the distribution cabinet, and ensure the stability and reliability of the power system.

Why use to Busbar Insulators and Busbar Clamps

Because busbar insulators and busbar clamps can protect the connection between the busbar and the distribution cabinet, insulators provide reliable insulation for the busbar and other components to prevent short circuits and leakage accidents, while busbar clamps firmly fix the busbar to ensure stable connection and provide stable power transmission for the system. Without the protection of busbar insulators and busbar clamps, the busbar may come into contact with other metal accessories or cabinets in the distribution cabinet to form a short circuit, or the connection may be loose and have poor contact, resulting in increased temperature at the connection point and causing safety accidents. This is why busbar insulators and busbar clamps are used in distribution cabinets. Everything is measured from the two aspects of safety and power system stability.

How to Install and Maintain

Installation of Busbar Insulators and Busbar Clamps

The correct installation of busbar insulators and busbar clamps in the distribution cabinet can ensure their stable function. Therefore, it is necessary to understand and follow the correct steps. The following are their specific installation steps:

1. Inspection & preparation

Before installation, we need to carefully check the busbar insulators and busbar clamps, check whether their models, sizes, and appearance meet the installation requirements. If there are any damage or defects in the appearance, they need to be replaced, and then prepare all the tools needed for the installation process. Finally, it is necessary to check and confirm that the foundation of the distribution cabinet has been installed and the installation meets the requirements.

2. Installation of busbar insulators

According to the design drawing and the layout of the busbar in the distribution cabinet, select a suitable installation position to ensure that the selected position allows the busbar to be always insulated. Generally, this position is between the support point and the joint of the busbar. Next, the bottom of the busbar insulator is fixed to the bracket of the distribution cabinet with bolts and tightened to ensure that the insulator and bracket are firmly fixed and flat.

3. Installation of busbar clamps

The busbar clamp is installed above the busbar insulator and fixed with bolts. The nut on the side of the busbar clamp is locked to ensure that the busbar insulator and the busbar clamp are firmly connected. Then put the busbar into the busbar clamp and tighten the busbar to ensure that the connection point of the busbar will not be loose or offset.

4. Testing and inspection

After installation, you first need to visually inspect the appearance of their installation to see if they are securely installed, whether the busbar clamps are aligned, whether the busbar fixing points are loose, etc. Then you need to use a megohmmeter to test the insulation resistance and the grounding resistance of the distribution cabinet. If it is a high-voltage system, a withstand voltage test is also required to ensure that their electrical performance meets the requirements and ensure the safety, reliability and stability of the equipment.

Maintain of Busbar Insulators and Busbar Clamps

In the distribution cabinet, the maintenance of the busbar insulator of the busbar clamp is the key to ensure that the busbar can provide a stable power transmission channel. In order to avoid the instability and safety hazards of the power system, we should perform maintenance according to the following points:

- Maintenance of busbar insulators: Regularly check whether the appearance of the busbar insulator is polluted, whether the appearance is damaged, and whether the connection of the insulator is firm. These factors will affect their insulation performance. Therefore, if these problems are found, we should clean the appearance or replace new busbar insulators in time.

- Maintenance of busbar clamps: For busbar clamps, the most important thing is to check whether the connection between them and the busbar and busbar insulator is loose, and whether their surface is corroded. If the busbar clamps are loose, they need to be tightened with a torque wrench to ensure that the bolts reach the designed torque, thereby providing a good fixation and support for the busbar.

How to Choose Busbar Insulators and Busbar Clamps

The distribution cabinet is the power control center. The selection of busbar insulators and busbar clamps can effectively improve the efficiency of the distribution cabinet in distributing power to the entire system and ensure the stability of the entire power system. Therefore, when choosing busbar insulators and busbar clamps, we need to consider their manufacturing materials, specifications, mechanical strength, installation methods, product manufacturing standards and machine certification, as well as the voltage level of the insulator, the conductivity of the busbar clamp, etc. Only when these standards meet the design requirements can the stability and safety of the busbar clamps and busbar insulators in the distribution cabinet be guaranteed.

FAQS

Q: What materials are busbar insulators generally made of?

A: Busbar insulators are generally made of ceramics, composite materials (such as silicone rubber, glass fiber), polymers (epoxy resin or silicone), plastics and rubber.

Q: How often should busbar insulators be maintained in the distribution cabinet?

A: The maintenance frequency of busbar insulators needs to be determined according to the working environment. It is generally recommended to maintain them once every 6 months to check their appearance, connection points and insulation performance.

Q: Can busbar clamps be reused?

A: Busbar clamps can generally be reused if they are not severely deformed or corroded on the surface. However, in order to ensure the safety of the electrical system, it needs to be judged by professional electrical engineers.

Conclusion

Busbar insulators and busbar clamps seem to be a very inconspicuous accessory in the distribution cabinet, but they can ensure the safe and stable operation of the distribution cabinet and the entire power system. Whether it is to provide mechanical support and electrical insulation for the busbar, or to improve the operating efficiency of the distribution cabinet, busbar insulators and busbar clamps are crucial. Therefore, after reading this blog, you will understand the key points of their installation and maintenance in the distribution cabinet, which will help you provide a safe and reliable electrical insulation solution for the distribution cabinet.

--- END ---

© Copyright 2024 China Haitan Electromechanical Technology Co., Ltd. All rights reserved.SUPPORT BY:JUNJ Privacy Policy

E-mail:

E-mail:  No. 20 Lingyun Road, Dongfeng

No. 20 Lingyun Road, Dongfeng