What is SMC Busbar Support?

1. Introduction

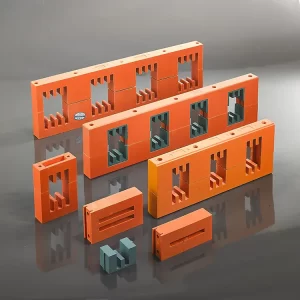

In modern electrical power distribution systems, SMC busbar support has become a critical component for ensuring both mechanical stability and electrical insulation. SMC busbar supports are designed to fix and insulate busbars, which are copper or aluminum conductors that carry large currents. You’ll find these bus bar supports in critical locations like switchgear, panel boards, substations, and renewable energy installations. Unlike traditional porcelain or metal insulators, SMC supports offer a unique combination of durability, electrical safety, and design flexibility, making them a modern and reliable choice for a wide range of applications.

By the end of this guide, you’ll understand what SMC busbar supports are, why they are used, their advantages over other materials, and how to choose the right support busbar solution for your project.

2. Why is SMC Material Used for Busbar Support?

2.1 What is SMC?

SMC stands for Sheet Moulding Compound, a thermoset composite material widely used in the electrical industry. It is manufactured from:

-

Resin matrix: Unsaturated polyester for high chemical resistance.

-

Reinforcement: Short glass fibers (15–30%) to improve tensile and flexural strength.

-

Fillers: Flame-retardant additives such as alumina trihydrate.

-

Stabilizers & pigments: To improve thermal resistance and design flexibility.

SMC is produced via compression molding at 120–160°C, resulting in a dense, void-free structure ideal for busbar supporting insulator applications.

2.2 Characteristics of SMC Materials

-

Dielectric strength: ≥12 kV/mm (ASTM D149), ensuring safe insulation.

-

Thermal stability: Continuous service up to 150–200°C.

-

Flame resistance: UL 94 V-0 self-extinguishing rating.

-

Moisture & UV resistance: Suitable for outdoor and coastal environments.

-

Dimensional stability: Low shrinkage and warpage, even under heavy load.

3. What are the Advantages of SMC Busbar Supports?

3.1 Lightweight Yet Durable Design

With a density of 1.8–2.0 g/cm³, SMC busbar support is 75% lighter than steel, reducing overall panel weight. Despite being lightweight, it withstands continuous vibration cycles, making it ideal for renewable energy systems like wind turbines.

3.2 High Mechanical Strength

SMC insulators provide a flexural strength of 150–250 MPa, comparable to cast iron but without brittleness. They can handle short-circuit forces and mechanical shocks without failure.

3.3 Excellent Insulation

Volume resistivity exceeds 10¹³ Ω·cm, preventing leakage currents and ensuring safety in compact switchgear and panel boards.

3.4 Thermal & Flame Resistance

SMC supports maintaining structural integrity during fault current events. With an HDT (Heat Distortion Temperature) above 200°C, they outperform most plastics and guarantee fire-safe performance.

3.5 Environmental Resistance

Unlike metal supports that rust, SMC supports resist corrosion, salt spray, and chemical attack. Their hydrophobic surface prevents tracking and ensures long service life even in humid conditions.

3.6 Customization Flexibility

SMC can be molded into complex shapes, allowing integrated mounting flanges, clips, and barriers. This design adaptability makes it a preferred choice for OEM switchgear manufacturers.

4. Applications of SMC Busbar Supports

-

Switchgear: Phase separation and support in LV/MV panels.

-

Distribution boards: Secure mounting of copper busbars.

-

Substations (1–36 kV): Mechanical and electrical isolation of conductors.

-

Renewable energy systems: Wind and solar power installations requiring vibration and UV resistance.

-

Industrial plants: Chemical-resistant SMC insulators used in corrosive environments.

5. SMC vs Other Busbar Support Materials

When engineers choose a busbar supporting insulator, the most common material options are SMC, porcelain, epoxy resin, and nylon. Each has unique electrical, thermal, and mechanical properties. Be

We break down the differences in a structured way so you can clearly understand where each material performs best and where it falls short.

5.1 SMC Busbar Support vs Porcelain Busbar Support

Porcelain has been the traditional choice for decades in substations and high-voltage applications. It provides very high dielectric strength and excellent resistance to weathering. However, it is also heavy and brittle, which means it can crack during installation or under mechanical shock.

In contrast, SMC busbar supports combine strong electrical insulation with a much lighter weight. The composite structure reinforced with glass fibers gives them 3–5 times higher impact resistance compared with porcelain, while still maintaining reliable insulation up to medium-voltage levels. Another key advantage is design flexibility: porcelain must be shaped and glazed in kilns, whereas SMC can be compression-molded into complex forms with integrated mounting points.

Engineering takeaway:

-

Choose porcelain if you are dealing with extra-high voltage (>36 kV) systems that require long-term field-proven ceramic performance.

-

Choose SMC for compact switchgear, panels, and renewables where weight reduction, shock resistance, and customized shapes are important.

5.2 SMC Busbar Support vs Epoxy Resin Busbar Support

Epoxy resins are widely used in electrical equipment because of their strong adhesion and chemical resistance. They can deliver high insulation values, but they are less effective under high mechanical stress. Standard epoxy supports usually achieve flexural strength in the 80–120 MPa range, which is adequate for many panels but lower than SMC’s 150–250 MPa capability.

Another consideration is manufacturing efficiency. Epoxy supports are cast and require long curing times—sometimes hours or days. By contrast, SMC can be compression-molded in just a few minutes, which greatly benefits mass production. Outdoors, epoxy materials often need extra stabilizers to resist UV radiation, while SMC naturally provides better protection against sunlight and moisture.

Engineering takeaway:

-

Choose epoxy if you need large monolithic parts or specialty molded components with very high dielectric requirements.

-

Choose SMC when you need faster production cycles, higher load-bearing ability, and inherent outdoor resistance.

5.3 SMC Busbar Support vs Nylon Busbar Support

Nylon (PA6 or PA66) is often used in low-cost or lightweight electrical applications. It has good impact strength and is easy to process. However, it suffers from creep under continuous load and absorbs moisture, which reduces dimensional stability. Thermally, nylon grades are usually limited to 160–180°C, compared to SMC which can withstand 200°C or more.

Flame resistance is another issue: standard nylon supports often only meet UL 94 HB or V-2, whereas SMC insulators consistently achieve UL 94 V-0, meaning they self-extinguish quickly without dripping. In heavy-duty busbar systems, nylon supports may deform over time, while SMC supports remain stable.

Engineering takeaway:

-

Choose nylon for lightweight, low-load indoor panels where cost is critical.

-

Choose SMC for medium- or high-current busbars that require long-term mechanical stability, flame safety, and minimal maintenance.

5.4 Beyond the Mainstream: Other Alternatives

-

FRP/GPO-3 Laminates: Fiberglass-reinforced polyester sheets are common in switchgear barriers and support parts. They have good dielectric strength and flame resistance, but less design flexibility compared with molded SMC.

-

DMC/BMC Compounds: Similar to SMC but optimized for smaller parts. They are economical for compact insulators but generally have lower strength and durability than high-grade SMC.

5.5 Comparative Overview

| Property | SMC | Porcelain | Epoxy Resin | Nylon (PA) |

|---|---|---|---|---|

| Dielectric Strength | High (≥12 kV/mm) | Very high (15–20) | Medium–high (10–15) | Moderate (5–8) |

| Flexural Strength | 150–250 MPa | 50–80 MPa | 80–120 MPa | 60–80 MPa (varies) |

| Thermal Capability | 200°C+ | High but brittle | 120–150°C | 160–180°C |

| Flame Resistance | UL 94 V-0/5VA | Inorganic, excellent | V-0 achievable | Mostly HB–V-2 |

| Weight | Light (1.8–2 g/cm³) | Heavy (2.3–2.6) | Moderate | Very light |

| Design Flexibility | High (moldable) | Low | Medium | Medium |

| Long-term Reliability | 25–30 years | 30+ years | 20 years | 10–15 years |

5.6 Key Decision Factors

-

Voltage class: Porcelain dominates at the highest voltages; SMC is ideal up to medium-voltage systems.

-

Mechanical load: SMC outperforms epoxy and nylon in handling short-circuit forces and vibration.

-

Environment: For outdoor and coastal sites, SMC provides natural resistance to moisture, salt, and UV.

-

Production efficiency: SMC supports are molded in minutes, while epoxy requires long curing.

-

Lifecycle cost: Nylon is cheaper upfront but has shorter service life; SMC balances cost with durability.

6. How to Choose SMC Busbar Supports

Choosing the right SMC busbar support is critical to ensure both electrical safety and long-term reliability. Engineers and procurement teams should evaluate the following factors before finalizing a design:

6.1 System Voltage

Always match the dielectric strength of the composite busbar insulator for panel boards to your system requirements. For example, a rating of ≥12 kV/mm is suitable for a 10 kV system. Higher voltage systems require proportionally greater insulation margins.

6.2 Mechanical Load

Check the flexural strength of the support. A value above 150 MPa ensures stability against short-circuit forces and vibration in heavy-duty switchgear and renewable energy installations.

6.3 Application Environment

-

Indoor use: For compact switchgear and busbar support for distribution box, standard SMC grades provide reliable insulation and durability.

-

Outdoor or renewable systems: Use UV-stabilized and anti-tracking formulations to resist sunlight, humidity, and salt spray.

6.4 Standards Compliance

Always confirm certifications before purchasing. Reliable supports must meet:

-

IEC 61439 (switchgear & controlgear assemblies)

-

UL 94 V-0 flame resistance

-

RoHS & REACH environmental compliance

These standards guarantee that the SMC insulator can withstand electrical stress while remaining eco-friendly.

6.5 Customization & Design Flexibility

One of the biggest advantages of SMC is its moldability. If your design requires integrated clips, mounting flanges, or phase barriers, ask your supplier about customized solutions. Many SMC busbar support manufacturers in China offer OEM/ODM services to match panel board layouts, reduce assembly steps, and lower overall system costs.

7. Conclusion

SMC busbar support has become the industry benchmark for low- and medium-voltage power systems, offering the ideal mix of mechanical strength, insulation safety, and design adaptability. Compared with porcelain, epoxy, and nylon supports, SMC provides superior flame resistance, long-term stability, and cost-effectiveness.

Whether you are designing switchgear, substations, or distribution boxes, using a composite busbar insulator for panel boards ensures safety, efficiency, and durability. For buyers seeking reliable sourcing, working with an experienced SMC busbar support manufacturerin China can provide high-quality products that comply with IEC and UL standards, along with cost advantages for global projects.

As power systems evolve toward smarter grids and renewable integration, busbar supporting insulators made from SMC will remain a vital component in ensuring stable, safe, and efficient electricity distribution worldwide.

--- END ---

© Copyright 2024 China Haitan Electromechanical Technology Co., Ltd. All rights reserved.SUPPORT BY:JUNJ Privacy Policy

E-mail:

E-mail:  No. 20 Lingyun Road, Dongfeng

No. 20 Lingyun Road, Dongfeng