5 Key Accessories you need to know about DIN Rails

DIN rails are the unsung heroes of electrical panel design. These standardized metal rails are used extensively in control cabinets and automation systems to mount industrial control equipment, circuit breakers, relays, power supplies, and more. But the real secret to a well-organized, safe, and scalable electrical installation lies in the DIN rail accessories that support them.

In this blog, we explore the 5 essential DIN rail mounting accessories that every electrical engineer, panel builder, or industrial automation professional should know. Whether you’re managing a small project or a complex industrial setup, choosing the right DIN rail terminal accessories ensures long-term reliability and operational efficiency.

5 Key DIN Rail Accessories You Need to Know

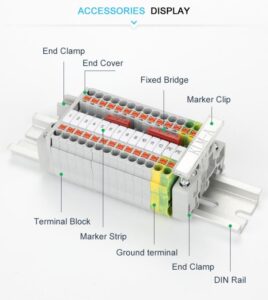

DIN Rail Terminal Blocks

What Are DIN Rail Terminal Blocks?

DIN rail terminal blocks are modular connection units mounted on DIN rails to facilitate secure electrical connections. They come in various types, including screw, spring, and push-in terminals, tailored for different current and voltage needs.

【DIN RAIL ACCESSORIES DISPLAY】

Function & Importance

Terminal blocks play a vital role in electrical signal distribution and circuit protection.

They:

- Provide neat cable management

- Allow quick maintenance

- Enable easy circuit separation and testing

| Type | Connection Method | Best For |

| Screw-type | Manual tightening | High-current loads |

| Spring-loaded | Tool-less installation | Quick assembly |

| Push-in | Tool-free push mechanism | Compact panels |

DIN Rail End Brackets (ST/STS Series)

What Are End Brackets?

End brackets (also called end stops) are small but critical DIN rail mounting accessories that secure terminal blocks and other components in place, preventing them from sliding along the rail.

Material Types

| Material | Pros | Applications |

| Polyamide (plastic) | Lightweight, non-conductive | General use |

| Metal (zinc-coated steel, aluminum) | High strength, durable | Harsh environments |

Installation Tips

- Use at least one end bracketon each side of your terminal block group.

- For vibration-prone applications, use metal bracketswith locking screws.

- ST Series (standard) vs STS Series (screw-secured): choose STS when stronger holding force is required.

DIN Rail Mounting Clips & Adapters

Purpose and Utility

Not every component is DIN rail ready. Mounting clips and adapters let you attach devices like small PCBs, enclosures, or sensors to DIN rails.

They are especially useful for:

- Converting panel-mount devices to DIN-compatible

- Installing custom electronics

- Modular retrofits

Material Considerations

| Material | Usage Notes |

| Stainless Steel | Corrosion resistance, outdoor enclosures |

| Plastic | Indoor panels, lightweight devices |

| Zinc-plated Steel | Budget-friendly and durable |

【plastic DIN Rail Mounting Clips】

DIN Rail Labels & Marking Systems

Importance of Labeling in Electrical Panels

Clear labeling reduces downtime, simplifies troubleshooting, and ensures compliance with electrical codes. Proper identification becomes critical in systems with hundreds of connections.

Types of Labels

- Clip-on terminal markers

- Adhesive wire labels

- Laser-printed device markers

- Color-coded ID strips

Use Cases

| Use Case | Recommended Labeling |

| Factory automation | Color-coded terminal strips |

| Building systems | Adhesive component tags |

| High-voltage panels | Warning/identification markers |

Pro Tip: Use thermal transfer printers for durable, smudge-resistant labels that withstand heat and chemicals.

Power Distribution Blocks & Busbars

Role in Power Management

These DIN rail terminal accessories distribute power efficiently to multiple circuits, reducing clutter and copper waste.

DIN Rail Mounted Busbars

- Available in single-phase, dual-phase, and three-phase formats

- Enhance load balancing

- Support standard modular protection devices

Comparison Table: Distribution Block vs. Busbar

| Feature | Power Distribution Block | DIN Rail Busbar |

| Best For | Branching power to multiple loads | Compact power distribution |

| Appearance | Enclosed with terminals | Exposed copper bar |

| Application | Larger systems | Compact control panels |

【Power distribution blocks (PDB) for DIN rails】

Wrapping It Up

Whether you’re designing a new control cabinet or retrofitting an old one, DIN rail accessories play a crucial role in making your setup safe, organized, and scalable. From terminal blocks and end brackets to labeling systems and busbars, each component is a building block in efficient electrical design.

At H&T, we specialize in providing top-quality DIN rail mounting accessories and DIN rail terminal accessories that meet international standards and industrial demands. Ready to upgrade your panel design?

Contact us today for product samples, engineering support, or a custom quote today!

--- END ---

© Copyright 2024 China Haitan Electromechanical Technology Co., Ltd. All rights reserved.SUPPORT BY:JUNJ Privacy Policy

E-mail:

E-mail:  No. 20 Lingyun Road, Dongfeng

No. 20 Lingyun Road, Dongfeng